June 13, 2024

The Power of One

ACE News

May 1, 2024 – When you go to the grocery store to pick up fresh produce, you’ll often pay per pound, but have you ever wondered just how accurate the scale at the register is?

If you were sized for a class ring in high school or college, do you remember the temperature of the room? Did you try on sample rings in hopes of finding the perfect match? Did you know others trying on rings before you could affect the metal’s temperature and your fit?

Metrology isn’t the first term that crosses our minds when we think of these every day or special life events, but its applications are critical and all around us.

“If we’re going to manufacture parts, it’s absolutely necessary that we measure those parts as well,” said Dr. Tony Schmitz, University of Tennessee professor and America’s Cutting Edge curriculum developer.

For years, America’s Cutting Edge has offered in-person bootcamps to those who complete the flagship online CNC machining course. The other courses ACE offers – metrology, composites and cybersecurity – have all been exclusively digital.

That is, until recently.

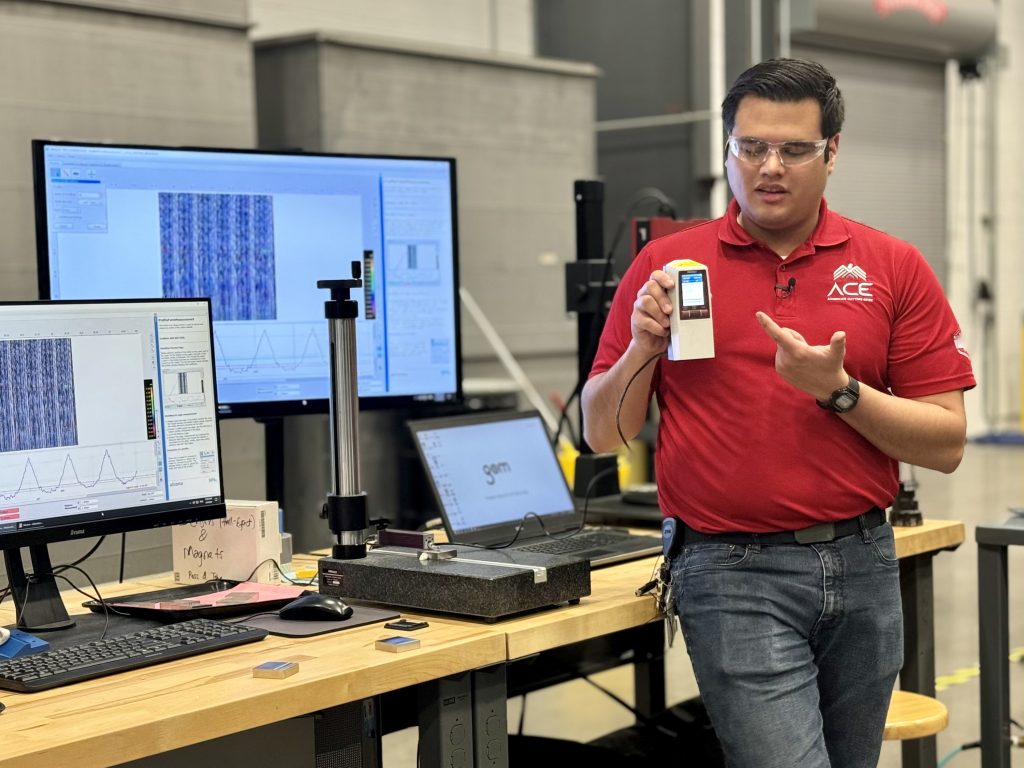

A brigade of high school students and teachers ranging from the upper secondary to postsecondary levels took to the University of Tennessee, Knoxville’s TN MADE facility April 8 and 9 for the inaugural metrology bootcamp.

The one-and-a-half day bootcamp introduced participants to a variety of metrology instruments, from calipers to CMM machines. Participants witnessed in real-time the impacts of environmental or other factors on the measurement of sample parts.

“There’s a lot of really good information that parallels with what we’re already doing,” said Elliott GeFellers, ACE trainer at Greene Technology Center. “It expands that tremendously.”

GeFellers says students have a lot to take away from in-person metrology training.

“They can see how it applies to the real world,” he said. “It’s not just being in a shop making a part. They can see there are standards.”

Those standards – reviewed during the bootcamp – come from the National Institute of Standards and Technology (NIST). They’ve created a framework that manufacturers use to reference as they perform measurements.

Bo Price, lead ACE instructor at the Tennessee College for Applied Technology – Knoxville, says those standards must be remembered at all times.

“I want students to understand that the inspection of parts that they’re putting out is as important as the cutting process,” he said.

Speaking of students, two from Oak Ridge High School (ORHS) attended the camp. Both are involved with FIRST Robotics, a community where many ACE participants have come from because of the use of machining in robotics. They say the information learned during the camp will have far-reaching applications.

“During robotics it’s more about getting things done, but now I can make things more precise and accurate,” said Elena Vogt.

“It’s benefitted me because now I know more about measurement techniques,” said Imelia Markus-Brock. “I feel that’ll be useful when I go to college and doing research, or work in my career.”

Dr. Mark Buckner teaches at ORHS, where he also leads Wildcat Manufacturing. The program focuses on manufacturing innovations.

Even for a seasoned professional such as him – having previously worked in standing up a secondary accreditation lab to NIST – the bootcamp introduced him to new instruments.

“The new thing was structured light scanning and using ZEISS software,” he said. “I’d love to be able to see in the future how to use it in reverse engineering and the creation of digital twins.”

While the bootcamp focuses heavily on instrumentation and terminology, Schmitz emphasized connections between the content and real-life situations. Is the scale at the store for your produce accurate? How warm or cool was it in the ring-sizing room?

“I wanted to provide context and additional information for why this is relevant,” said Schmitz. “Making connections between things I’ve learned and experiences I’ve had is a great outcome for this program.”

As for what happens next, Pellissippi State Community College’s Andy Polnicki believes the training can easily be integrated into existing curriculum.

“It’s the type of content we can add to an introduction class we have in the mechanical department – before they get to those advanced classes later,” said Polnicki. “There is value to this content and how it links to industry needs.”

Future metrology bootcamps are being planned, but the no-cost, online metrology course is available now and takes only about two hours to complete. Click here to register.

Take the first step toward starting or advancing your career in machining.