March 29, 2025

Mastercam: Manufacturing companies who don’t use this will miss out

ACE News

March 15, 2023 – “This effort to train the next generation workforce, from entrepreneurs to machinists, is a dream come true,” says Dr. Tony Schmitz, developer of the America’s Cutting Edge (ACE) curriculum. “It’s the culmination of all the things I’ve learned and taught in a compact, efficient way.” Proven successful on a local level, the program is now being scaled up nationally.

Since the online ACE training for Computer Numerical Control (CNC) machining was launched in December 2020, Tony has nurtured its steady growth to nearly 3,700 students from all 50 states. He serves as joint faculty for mechanical engineering at both the University of Tennessee, Knoxville (UT) and Oak Ridge National Laboratory (ORNL). He also leads several of the five day, in-person ACE training called bootcamps, where more than 300 students have gotten hands-on CNC experience within the past two years. Each student machines four parts of an oscillating piston air engine that they assemble and keep as part of the training.

The national testbed for ACE in East Tennessee has been so effective, that it has expanded regional machine tools workforce training and development centers in a hub and spoke model in North Carolina, Texas, West Virginia, and Florida with more states to come. “We established the ACE program because machine tools and machining are critical for the United States,” Tony emphasizes. ACE is supported by the U.S. Department of Defense (DoD) and managed by the Institute for Advanced Composites Manufacturing Innovation (IACMI), but how is the program scaling up?

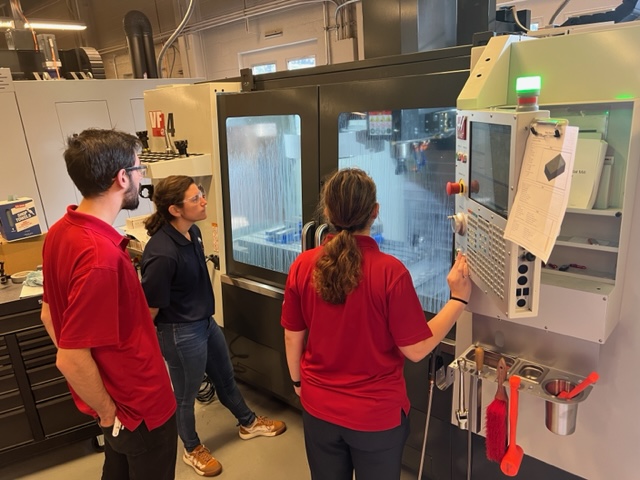

Through a model called “train-the-trainer,” Schmitz and UT PhD students Emma Betters, Aaron Cornelius, Jake Dvorak, and Jose Nazario have developed a toolkit for educators to use and guide them step-by-step through the bootcamp so that they can become future ACE instructors. Emma says, “I look forward to seeing it spread to other places, a full range of high schools to undergrads to graduate students. Getting kids excited from a younger age, understanding that manufacturing offers a viable career they can do, is really important.”

FLORIDA

One of the newer ACE hubs is the alma mater for both Tony and Emma, the Herbert Wertheim College of Engineering at the University of Florida (UF). To get the full ACE experience, UF sent two teaching assistants as participants and one professor for train-the-trainer last summer so that all three would be prepared to teach the ACE curriculum. UF professor Sean Niemi says, “I want to completely revitalize the design and manufacturing curriculum we have for mechanical engineering at UF. I want to bridge to other departments so that anyone can do this. My goal is to reach a broad range of people who could benefit from these skills.”

In his first year of graduate school, Ilan Zarin is ready to see more hands-on CNC opportunities for UF students. “Giving them experience on these machines would be a game changer. Up until rather recently, designing and machining have been two different things. Once you get the hands-on learning and realize how to make practical designs, THEN you become a good designer.”

This couldn’t come at a better time for Florida. “COVID showed that the state was overly dependent on tourism,” Sean explains. “So now the state is focused on growing manufacturing and expanding the aerospace and defense industries. As someone who teaches mechanical design courses and enjoys manufacturing, I’m excited to see all the elements I’m passionate about coalesce in the ACE program.”

WEST VIRGINIA

Rick Smoot is another educator sent to become a trainer for Marshall University’s Robert C. Byrd Institute (RCBI). Rick has been a machinist for 40 years–he says as far back as when design was done with a calculator and pencil. Through ACE, he’s learning Computer Aided Manufacturing (CAM) software for the first time. “CAM is more user-friendly and intuitive,” shares Rick. “If you better understand the design aspect, you can get a deeper understanding of how it should be machined. That’s a plus, plus to me.”

Rick has been pleased with how the ACE curriculum is expanding in West Virginia, Kentucky, and Ohio because he’s focused on national economic concerns. “We’re a nation of purchasers instead of producers. Manufacturing needs to be a big part of our economy. If our economy is more self-sustainable, we create more jobs and keep the money in our country. It all goes together to keep that engine running.”

Looking around the lab at students who are proud of what they’re making at ACE, Rick is optimistic. “Many of us older guys are retiring. I’m very hopeful when I see young people come into the industry where a lot is changing in technology. They’re learning the new skills they need.”

TENNESSEE

Closer to home, ACE is attracting a diverse group of educators looking to re-envision how to attract and train the next generation of manufacturers, from high school teachers to technical schools, from community colleges to universities. Chancellor Donde Plowman is thrilled the University of Tennessee, Knoxville makes that happen. “We know not everybody needs a four-year degree, but everybody needs a great job. There’s faculty, graduate students, adult learners, all mingling respectfully. You can feel engaged learning going on. I’m really touched by that and proud.”

Tennessee high school teachers from Rhea, Hamblen, Anderson, and Knox counties all want to know how they can start bridging the country’s skills gap starting with courses for teenagers. Craig Short from Morristown West High School knows there are many local jobs in the automotive industry that will pay a starting wage of $24 an hour for high school graduates. “I’m in for anything I can learn for the kids,” says Craig. “I was in the machine industry for 22 years, and without a dad, I feel my machine shop teacher made a huge impact in my life. I’m trying to make a difference.”

Some teachers haven’t gotten the chance to get that hands-on experience until now. Nathan Kenner from West High School in Knoxville jumped at this training opportunity. “I’m here to learn how to machine and how the systems and science work. It’s more important for me to experience the student side of it. I’ve never experienced machining in my life. So, this is all new to me and really cool.” Nathan works with students all four years who have chosen machining as their elective. His students have specifically requested CNC opportunities. He adds, “They want it, they value it. Once they see the direct value, then they’ll be more engaged, and learning becomes more effective.”

Through grants, some high schools already have CNC machines and are working with local industries to fill a need. Most companies have smaller jobs with lower quantities that are not as profitable but need to be made. High schoolers properly trained could machine those parts, bringing income back to the students and the school. Dr. Mark Buckner at Oak Ridge High School explains, “At Wildcat Manufacturing, we’re setting up a business model to sustain the program and give students job experience. It’s a win all around.”

Justin Beaty is looking to do something similar in Rhea County Schools and sees it as a way to keep talent close to home. Justin is hearing from local manufacturers: “We need people. The next 10 years, many workers will retire, and we’re not seeing the new hires coming in. If you can train them, we will hire them.” After a week of instruction, Justin feels ACE gives him the tools to serve many needs in his community. Plus, it’s been a lot of fun personally. “I’m a big maker myself. Seeing that blank of material be transformed into something else and knowing I had a hand in it is rewarding. I’m going to be an evangelist and will tell others about ACE.”

That’s music to Tony Schmitz’s ears. He knows if we don’t work quickly, we could have 2.1 million unfilled jobs in U.S. manufacturing by 2030. He concludes, “We’re looking for an evangelizing community to take this message national and we want nothing less than eliminating the shortfall in the manufacturing workforce that exists today.”

Take the first step toward starting or advancing your career in machining.